We’ve come to expect every generation of iPhone to be smaller, lighter, faster.

What we don’t realize, however, is while our phones are indeed becoming smaller, lighter and faster, the device is profoundly different than its flip-open counterpart.

What we’ve perceived as a natural progression actually required a huge leap in fundamental science over the past 15 years. This science goes beyond mixing chemicals in a lab to laying the theoretical framework for ideas made tangible. The result is technology so seamless, we don’t realize what we’re holding in our hands.

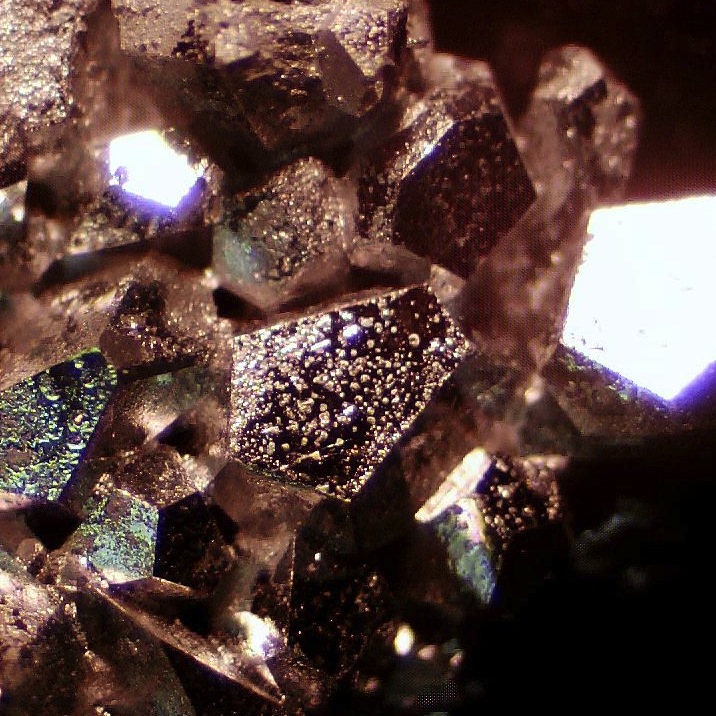

In the College of Liberal Arts and Sciences, we call this complex materials research. When the goal is smaller, lighter, faster, materials set the speed limit. Eventually, traditional building blocks reach their limit to developing new technology. By creating novel materials such as crystals, magnets, metals and others, researchers in LAS and the Department of Energy’s Ames Laboratory are constructing new building blocks to push technology further.

“The products of condensed matter physics are all around us,” Paul Canfield, a Distinguished Professor of physics and astronomy in LAS, said. “And one of the successes of condensed matter physics is the fact that people take it for granted. It’s invisible to many people.”

LAS is where discovery meets technology. Our fundamental science is why Apple can manufacture a phone that’s, well, smaller, lighter and faster. It’s why a surgeon’s tools can be made more durable. It’s why a company can harvest more solar power for their facilities.

Science for all

A cell phone contains hundreds of different types of materials that allow it to show you the time, weather and score all while SnapChat-ing with a friend. And, it fits in your pocket. Fifty years ago, the same technology would have taken up the entire floor of a building and would have been able to do far less, Canfield said. “The computers used for the Manhattan Project were something you could now fit into the size of a wristwatch.”

“New materials enable manufacturers to make electronic devices smaller, more powerful, more sophisticated and, in many cases, less expensive,” Beate Schmittmann, dean of the LAS college, said. This leads to tangible solutions to problems and inefficiencies in energy production, clean air and water, national security and healthcare.

“There is no area of modern society and, in particular, modern technology that does not in some form or fashion rely heavily on complex materials,” she said. “And Iowa State University is known worldwide for its research in this field.”

Better science, better healthcare

“Magnesium diboride.” Ever heard of it? Probably not, but someday, if you need an MRI scan, you’ll be grateful for it. In 2001, Canfield – also a physicist at the Ames Laboratory and the Robert Allen Wright Professor in Physics and Astronomy – and his colleagues proved magnesium diboride was a cheap and useful superconducting material. Today, solenoids (a coil of wire that generates a uniform magnetic field) are being crafted out of wires spun from magnesium diboride. Those solenoids could allow MRI machines to be easier to access, cost less, and use less energy thanks to significantly lower cooler requirements.

LAS’ research in complex materials is leading to many other improvements in healthcare. In addition to a more affordable MRI scan, our scientists are discovering ways to make surgical tools more durable and medical imaging sharper – sharp enough to some day see inside a human cell.

Pat Thiel’s research could lead to more durable coatings for everything from surgical tools to nonstick cookware. Thiel is a Distinguished Professor of chemistry in LAS and a scientist at the Ames Laboratory. Her research focuses on surface chemistry, specifically quasicrystals. Her research is critical to work with complex materials because “to be able to create complex materials,” she said, “it all starts on the surface.”

Quasicrystals were discovered in the late 1980s by Israeli researcher Dan Shechtman. His research earned him the 2011 Nobel Prize for Chemistry, and he spends several months each year working at ISU and the Ames Laboratory. Quasicrystals have fundamental properties that include low friction, oxidation resistance, and hardness. They could lead to better metal coatings, stronger razor blades, and ultra-fine needles used in medical fields.

Perhaps someday, “going to the doctor” won’t be all that bad.

Illuminating the future

There are many ways research in new materials is paving the way for a better life. For example, LAS scientists are studying the way light’s momentum can transfer energy to objects, leading to better solar energy harvesting. Researchers use metamaterials to study this light-to-energy transfer.

Costas Soukoulis, a Distinguished Professor of physics and astronomy and an Ames Laboratory physicist, has been studying metamaterials for years. Metamaterials are manmade structures that create optical and magnetic properties not found in nature. Soukoulis, the Frances M. Craig Professor of Physics and Astronomy, said because they have a negative index of refraction, scientists could create “super lenses,” which could allow them to distinguish a distance equal to a wavelength. A super lens could one day be strong enough to see the details of a DNA molecule.

Soukoulis and his colleagues are working on a way to enhance the force of light on matter. Most of the time, the momentum of light and its associated forces are too small to notice. But at a nanoscale level, the effect can be quite large. Ames Laboratory scientists are using these forces to dynamically manipulate optical wavelengths at a nanoscale level.

This is all done with metamaterials, which can absorb all light, or bend light backwards.

Soukoulis is also working with graphene, a material used for manipulating terahertz waves (which operate at frequencies between microwave and infrared). Graphene could one day be used to make metamaterial devices that would have a superior ability to tune electrical responses for real-world solutions to solar power, telecommunications and medical imaging, meaning, this technology could lead to the design of mechanical devices activated entirely by light.

A myriad of opportunity

Complex materials are vital ingredients of the tiniest electronics, fastest computers, advanced batteries in hybrid cars, and giant wind turbines. They’ll create more durable tools for surgery, more reliable cooking surfaces, more efficient medical machines, and sharper medical images.

Complex materials research at the Ames Laboratory and in the College of Liberal Arts and Sciences offers a promise of a better world, and our discoveries are leading to tangible applications at a crucial time.

“This is something that is going to be important for us in the foreseeable future,” Schmittmann said. “I see no end in sight. The sky is the limit.”