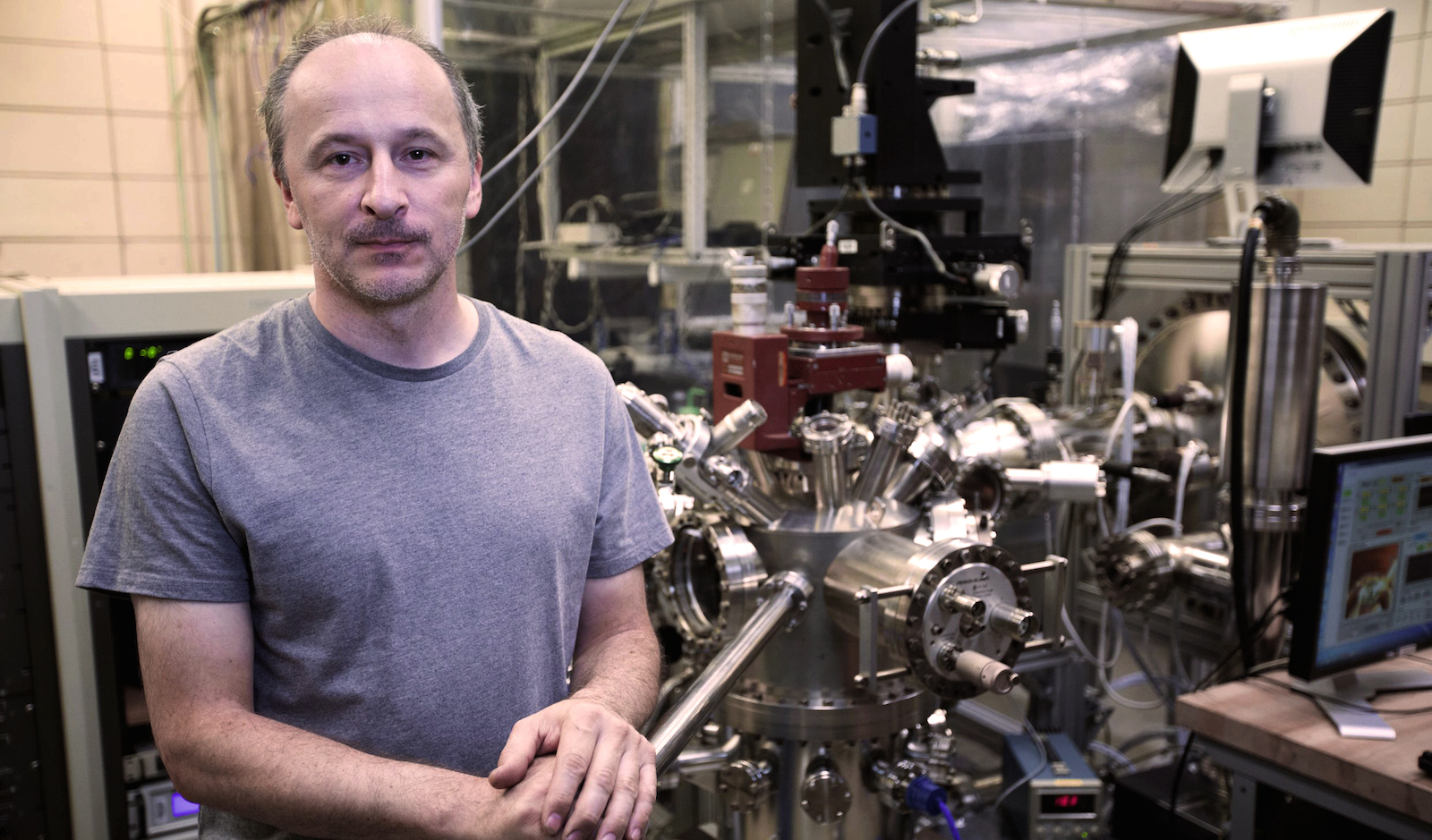

If you need your snow blower or your coffee maker fixed, Adam Kaminski is your guy.

Since elementary school, Kaminski has been taking apart, fixing and rebuilding machines to understand how things work. His fascination with technical devices has even earned him the title of “Doctor of All Machines” among some of his graduate students.

“Anything mechanical I would just take apart, which got me in trouble quite a few times,” Kaminski, a professor in the Department of Physics and Astronomy and a physicist at the Department of Energy's (DOE) Ames Laboratory, said. “It’s just curiosity — if you have a black box you want to know what’s inside.”

“Anything mechanical I would just take apart, which got me in trouble quite a few times,” Kaminski said. “It’s just curiosity — if you have a black box you want to know what’s inside.”

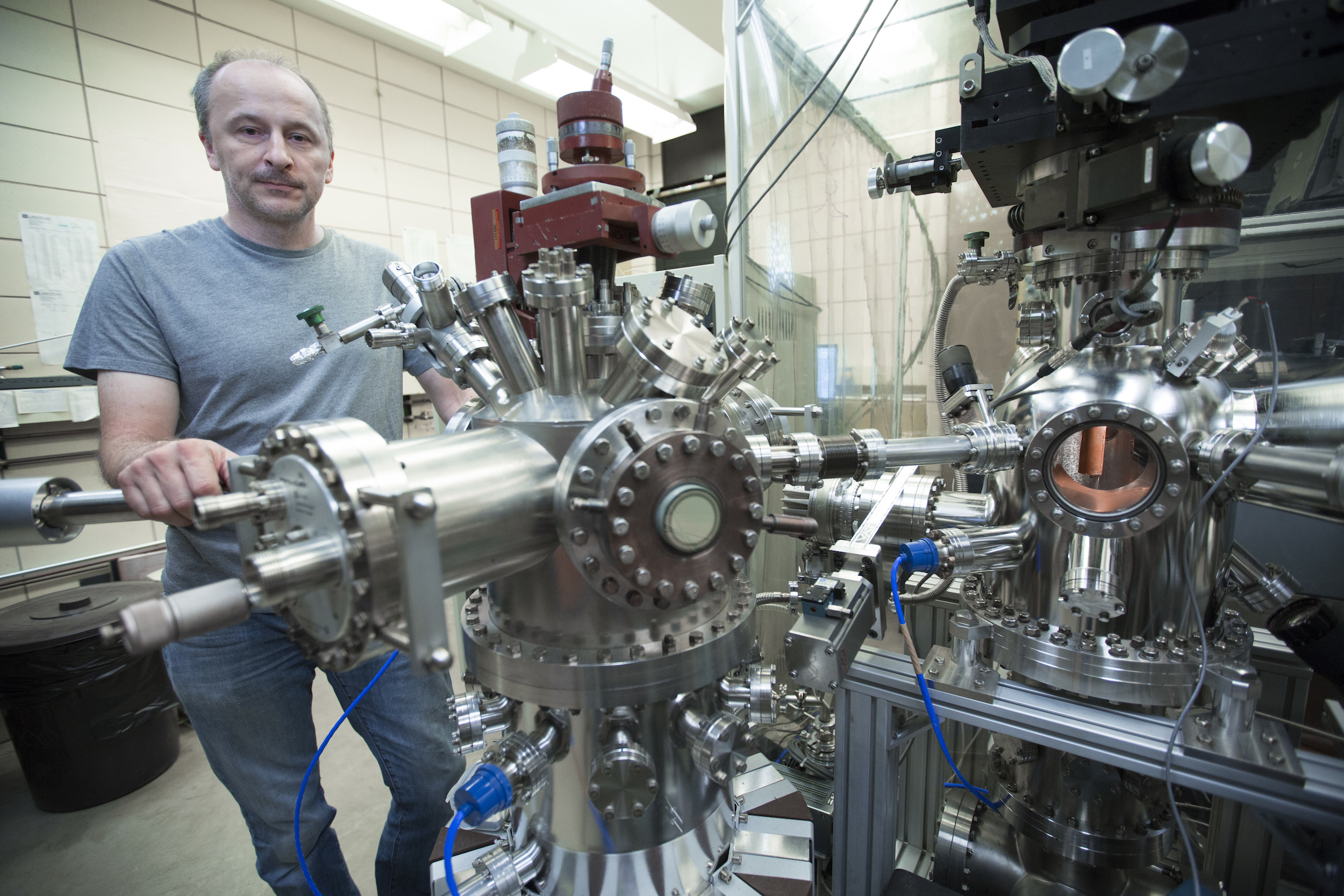

That curiosity, coupled with years of persistence, enabled Kaminski to build the first – and so far, only – machine of its kind in the world. It is called a “tunable laser angle-resolved photoemission spectrometer,” or tunable laser ARPES, and it has allowed Kaminski and physicists around the globe to pursue new research in materials science. New research that might someday be used to enhance the sensitivity of medical imaging; build more efficient, compact and lightweight generators for wind turbines; build computers that are 100 times faster and use 100 times less energy; and more possibilities that have not been conceived yet.

But to Kaminski, the prestige does not matter. He is just excited to know it works.

Driving technological progress

Kaminski is one step ahead in researching the materials that could make up the machines of tomorrow. The unique properties of these materials, metal-like compounds with special magnetic and electronic properties, may help reduce the energy consumption of electronics to nearly nothing.

“New materials are driving technological progress in society,” he said. “That’s what we are looking for.”

To research the most promising materials of the future, Kaminski needed technology that did not yet exist. He wanted to study the widest range of materials for longer lengths of time, and so his idea to build the tunable laser ARPES was born. A key part of the new machine, however, would be a laser that did not exist either.

“This is the best way to do this experiment,” Kaminski said of using the machine he built. “It is the cleanest, the most efficient, and you achieve the highest possible specs. You can look at materials that other people have looked at before and you can see completely new things that were not possible with the traditional approach.”

A new light source

Kaminski uses light to eject electrons from the materials he studies in order to see their properties. The traditional approach uses a light source called a “synchrotron,” a relativistic electron storage ring that produces electromagnetic radiation in the form of light. Synchrotrons are typically the size of a football field, and they are not readily available for any researcher to use.

The first disadvantage of using a synchrotron is the application required for approval to use the machine at all. After granted access, he had a small window of time to gather all his data. If he got an interesting result, he usually did not have time to rerun the experiment and confirm it, and it could take six months before he could use the synchrotron again.

“When I started my own research group the first thing I did was build a spectrometer-based helium discharge lamp,” Kaminski said.

With a helium discharge lamp, he could study materials in his own lab. The results were clearer and he had unlimited time to use it, but it was not “tunable,” meaning it would work for some materials, but not for others.

A low-energy, tunable laser would give him the resolution and the tunability he needed.

The only problem was the laser did not exist.

“The first machine I built was from available components,” Kaminski said. “With a laser, the complication was the significant learning curve and time required to develop the components.”

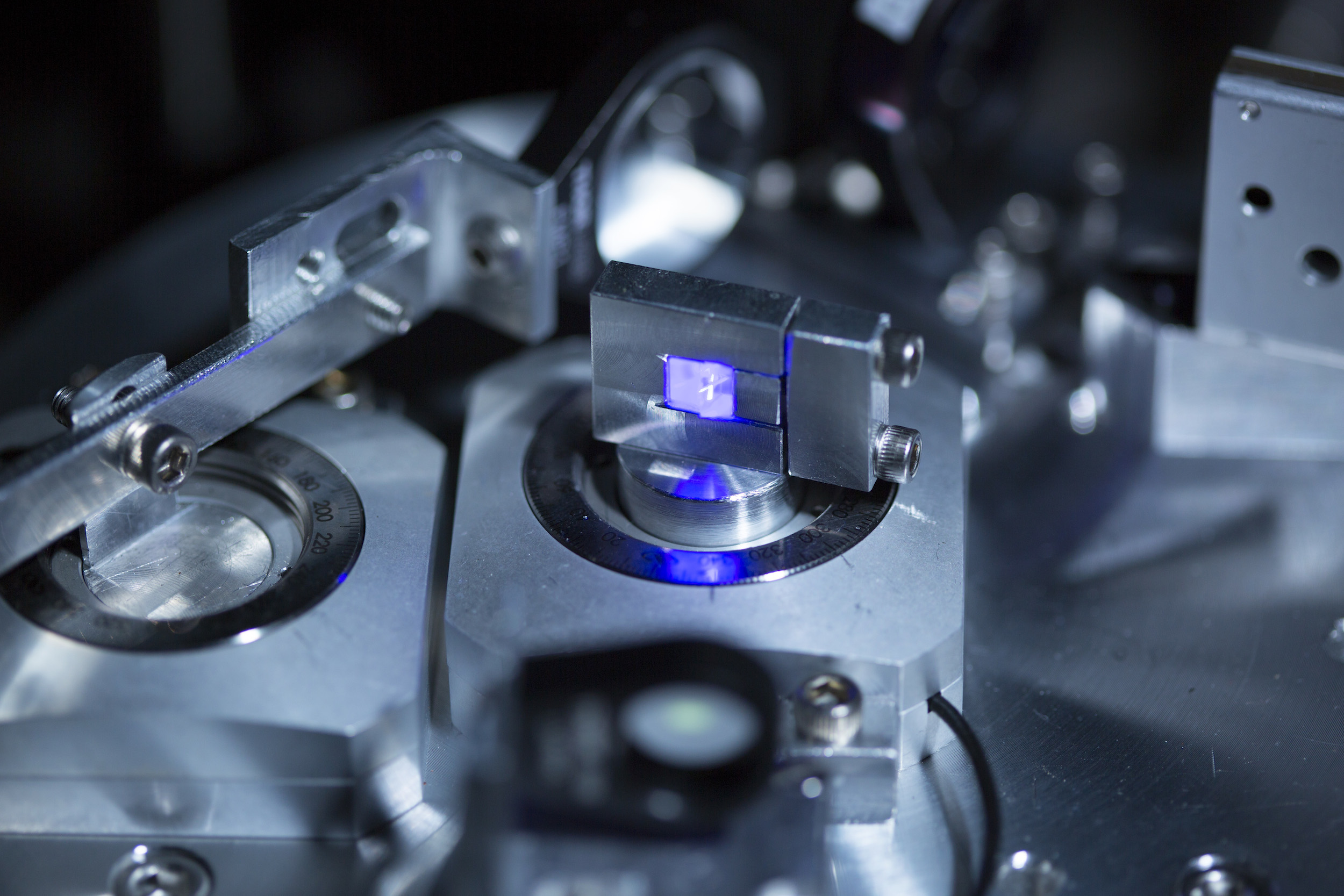

He decided to enhance a low-energy commercial laser to make it tunable. But to do this, he would need potassium borofluoride crystals – the only crystals known that can be used to quadruple the frequency of a laser beam. These crystals were originally discovered in China in the 1990s, but exports were embargoed. It became another hurdle Kaminski was determined to jump.

In 2009, he collaborated with a research group at Clemson University to develop a technique for growing these crystals in America.

"Each one is worth much more than a diamond because it takes six to eight months to grow," Kaminski said.

"Each one is worth much more than a diamond because it takes six to eight months to grow," Kaminski said.

Growing them turned out to be a smaller challenge than learning how to correctly cut and polish them. Soft like chalk and structured in layers, the crystals would bend, making them unusable, if cut incorrectly. It was a stressful task, but growing and polishing the crystals would not be the last challenge he faced in building the tunable laser ARPES.

Overcoming challenges

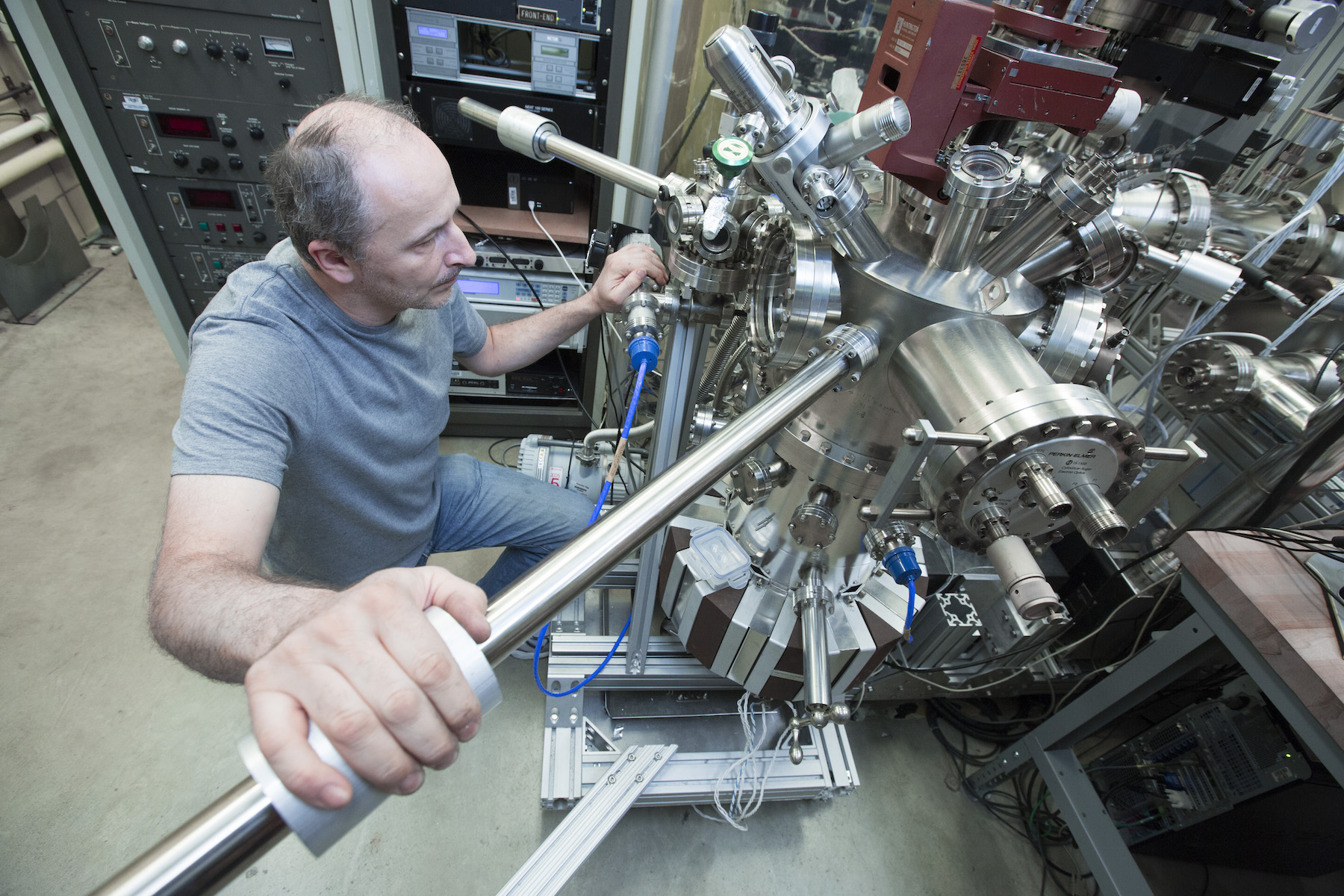

Things started out well. The Ames Laboratory provided $850,000 to help construct the tunable laser ARPES, which included developing the optical system for doubling and then quadrupling the laser beam energy, designing and constructing an ultrahigh vacuum system, integrating a commercial energy analyzer and optimizing its performance for low energy electrons, developing a low temperature sample environment and more. The process was long and required careful calibrations.

First, he encountered problems with the stability of the lasers. Then, issues with the energy analyzer arose.

And then the Earth’s magnetic field got in the way.

“The photoelectrons we study are emitted at very low kinetic energy,” Kaminski said. “Thus very small fields — such as Earth’s magnetic field — affect them. We use very good shielding in our chamber, but even then the whole system has to be oriented along east-west lines to minimize the effects of Earth’s magnetic field.”

Advancing innovative research

Finally, in 2014 after five years of collaboration, construction and calibration, all Kaminski’s hard work paid off when he published the first paper using the tunable laser ARPES.

Since then, more than a dozen papers using it have been published in high-profile physics journals. The machine has been used by a number of research groups at Ames Laboratory, and researchers at Sandia National Laboratory and Princeton University also use the machine.

Every day the tunable laser ARPES facilitates cutting-edge materials research by allowing scientists to study the properties of electrons in materials, thereby shedding light on the materials of the future. It also provides students a unique opportunity to use the machine.

“Being able to load the sample and do the measurement here and have the students actually gain experience — measuring, getting data and analyzing data — that’s really nice,” Kaminski said.

Na Hyun Jo, a graduate student in the Department of Physics and Astronomy, is one of many students inspired by his research and teaching. When she struggled to move forward in her doctoral studies, Kaminski helped her take the next steps.

“He is a hero for me,” Jo said. “He trusts students and encourages them to go further.”

She said that beyond being great at physics, he is known for his understanding of machines. He is already working on a new advancement for the tunable laser ARPES system.

“Whenever a machine, even a little espresso machine, is broken that no one can fix, he comes, opens the machine, diagnoses it, and fixes it like a doctor of all machines,” she said. “Owing to this amazing ability, he was able to build the tunable laser ARPES. His new, low temperature ARPES is pushing another limit. When his current project succeeds, it will be a big breakthrough that can open a new route to explore new physics.”